Table Of Contents

- How does UV work?

- Advantages

- Disadvantages

Listen to this audio

Ultraviolet Light For Disinfection

How Does UV Work?

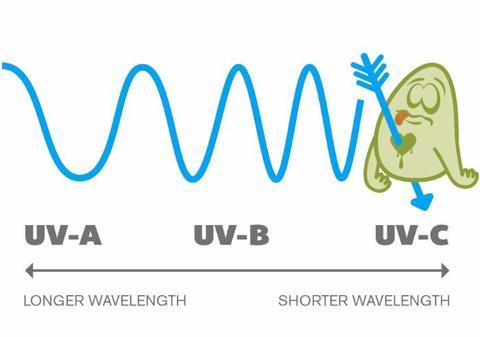

UV light for disinfection exists inside the range of light somewhere in the field of 10 and 400 nm. The germicidal scope of UV is inside the 100-280nm frequencies, known as UV-C, with the pinnacle frequency for the germicidal movement being 265 nm. This scope of uv light for disinfection has been consumed by the DNA and RNA of microorganisms, which causes changes in the DNA and RNA structure, delivering the microbes unequipped for reproducing. A cell that can’t duplicate is viewed as dead; since it can’t increase to overwhelming numbers inside a host. It is the reason UV cleansing is some of the time called bright germicidal light (UVGI).

What is UV Effective Against?

UV has been demonstrated successfully against a wide range of microorganisms. Infections contain RNA or DNA and are therefore defenseless to illumination. Microbes and parasites both contain DNA and are comparably helpless against uv light for disinfection. Spores are additionally powerless to UV. With the longstanding utilization of UV for sterilization, there is plenty of data regarding measurements necessary to inactivate various microorganisms. Microscopic organisms are commonly simpler to deactivate the virus, with parasites and spores being significantly harder to inactivate with UV.

Advantages

While there are distinct constraints to UV-C purification innovations, there are numerous advantages also. Sanitization times are quick, with a normal sterilization cycle enduring around 15 minutes. It takes into account rapid turnover times for rooms or different spaces has cleaned. Because of its effortlessness, UV-C sterilization is amazingly straightforward. All surfaces inside specific separation will watch a guaranteed degree of sanitization in a particular measure of time as long as the light has hindered from sparkling on that surface.

Security

As UV-C gives radiation, it hasn’t sheltered to be in the room while UV-C sterilization is occurring. UV-C has delegated “sensibly foreseen to be a human cancer-causing agent” by the National Toxicology Program. It presents a peril to skin and eyes, so immediate presentation to UV-C is consistently to stay away. UV-C is obstructed by various materials, including glass and most clear plastics. It is conceivable to securely watch a UV-C framework if you are glancing through a window. UV-C gives buildup free sterilization, so there is no worry over risky deposits that should be cleaned down or killed after the purification happens.

UV Light’s Effect on Bacteria

Disadvantages

Application

The ultraviolet light for disinfection can be utilized for an assortment of sterilization applications. As referenced, it has, for quite some time, been accessible for Biological Safety Cabinet purification. It can likewise utilize for surface and air cleansing in rooms and different chambers. It gives a compound free technique for sanitizing soundproofing materials that are customarily artificially incongruent. Littler UV-C frameworks are accessible for device and little thing sanitization inside a self-encased chamber. Structures for HEPA channel purification are available as are in-line conduit frameworks.